From solutions to productions, we’re specialized in making the products you need.

News categories

Product categories

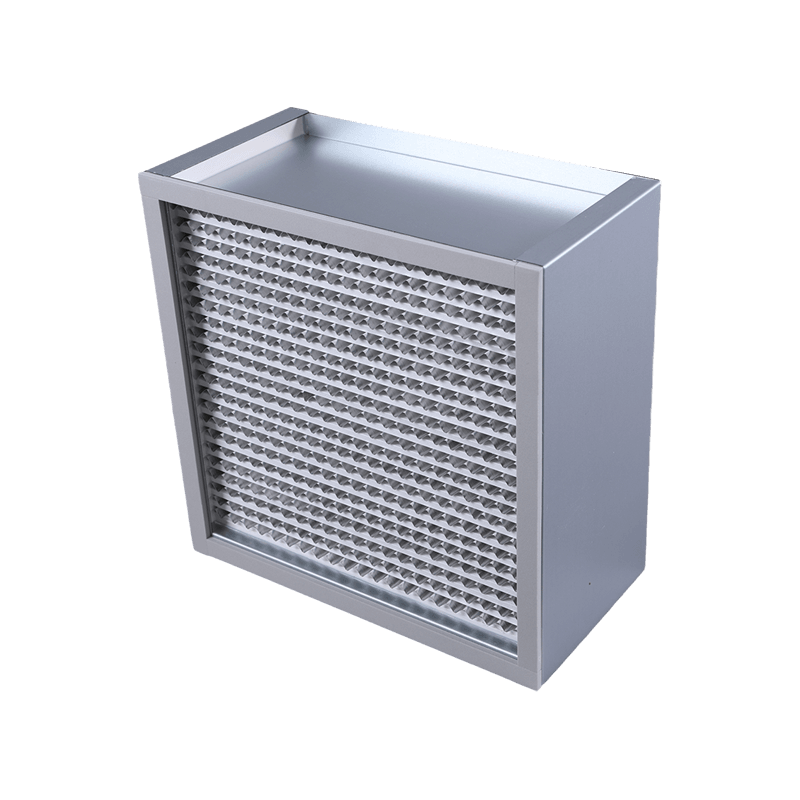

How are box HEPA filters tested and certified for safety and effectiveness?

Box HEPA filters are tested and certified for safety and effectiveness through a series of rigorous procedures designed to ensure they meet specific standards for air filtration. The following steps outline the common methods and standards used in the testing and certification process:

HEPA filters are typically required to meet certain industry standards, such as:ISO 29463 and EN 1822: These standards specify the classification, testing, and marking of high-efficiency particulate air (HEPA) filters.U.S. Department of Energy (DOE) Standard: DOE defines HEPA filters as having a minimum efficiency of 99.97% for removing particles 0.3 micrometers in diameter.Material Integrity: The filter media (usually made from glass fibers) is tested for physical integrity to ensure it can withstand the operational environment.Frame and Seal Testing: The construction of the filter, including the frame and seals, is evaluated to ensure there are no leaks or weaknesses that could compromise performance.MPPS (Most Penetrating Particle Size) Testing: HEPA filters are tested for their ability to capture particles at the most penetrating particle size (typically around 0.3 micrometers). This is usually done using aerosol generators and particle counters.

Penetration Efficiency: Filters are subjected to aerosolized particles, and the number of particles that pass through the filter is measured to determine the penetration efficiency. The goal is to achieve at least 99.97% efficiency for 0.3-micrometer particles.

Pressure Drop Measurement: The resistance to airflow (pressure drop) across the filter is measured. This ensures the filter can maintain adequate airflow while still providing high filtration efficiency.Scan Testing: The entire surface of the filter is scanned using a probe to detect any leaks or defects. This is often performed using an aerosol challenge and scanning the downstream side of the filter to ensure no particles are bypassing the filter media.

Bubble Point Testing: This test involves applying a liquid to the filter media and observing the pressure at which bubbles form, indicating potential leakage points.Environmental Exposure: Filters are exposed to various environmental conditions, such as temperature and humidity, to ensure they can withstand operational environments without degradation.Mechanical Stress Testing: Filters may undergo mechanical stress tests, including vibration and shock, to ensure they maintain integrity under physical stress.Certification by Accredited Bodies: Filters that pass all required tests are certified by accredited testing bodies. Certification typically involves documentation that specifies the filter’s performance characteristics, including efficiency, pressure drop, and leakage rate.Labeling Requirements: Certified filters are labeled with relevant information, including efficiency rating, test standards met, and other performance characteristics. This labeling ensures end-users can identify certified filters that meet required standards.Batch Testing: Manufacturers often conduct batch testing of filters during production to ensure consistency and quality. This includes retesting samples from production batches to verify they meet the required specifications.Field Performance Verification: In some cases, filters are tested in actual operating conditions to verify their performance in real-world applications.

Testing and certification of box HEPA filters involve a combination of material integrity checks, particle counting, airflow resistance, leak testing, and environmental durability assessments. These rigorous procedures ensure that the filters meet the high standards required for safety and effectiveness in various applications, providing reliable and efficient air filtration.

What factors affect the lifespan of a cylindrical filter and how often should it be replaced or cleaned?

What are the environmental benefits of using medium efficiency air filters?

related products

Copyright 2023 Nantong Henka Environment Solutions Co.,Ltd. All Rights Reserved

English

English русский

русский Español

Español 简体中文

简体中文