From solutions to productions, we’re specialized in making the products you need.

News categories

Product categories

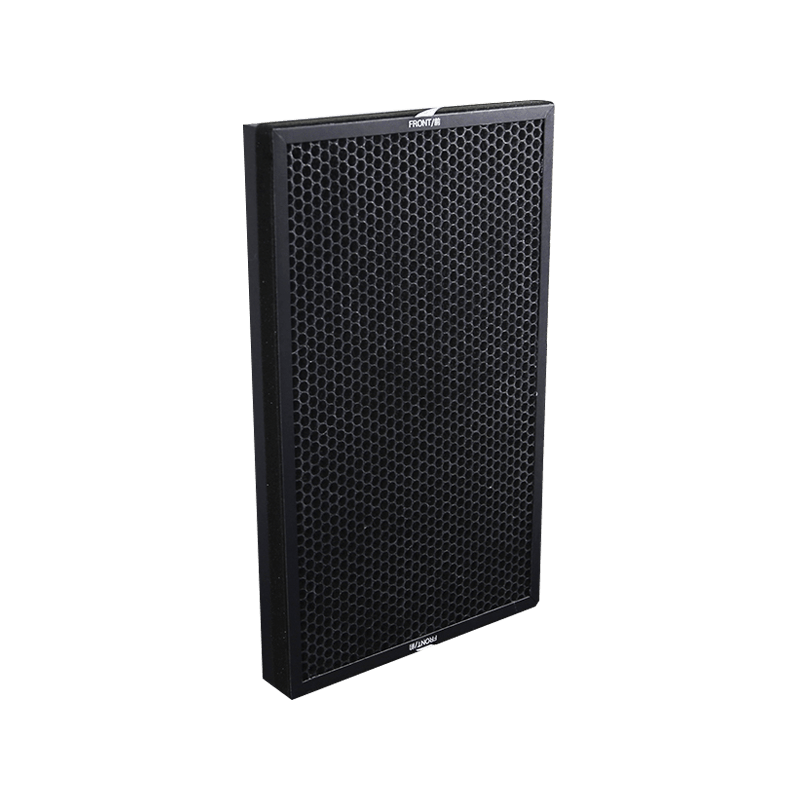

How does the thickness or depth of a panel air filter affect its filtration efficiency and airflow resistance?

The thickness or depth of a panel air filter plays a crucial role in balancing filtration efficiency and airflow resistance. Here’s how:

Increased Depth Enhances Filtration: Thicker or deeper panel air filters generally have more surface area to capture airborne particles, resulting in improved filtration efficiency. The additional layers or pleats in a thicker filter allow for the trapping of more contaminants, including smaller particles like dust, pollen, and mold spores.

Multiple Filtration Stages: Deeper filters may incorporate multiple filtration stages, each designed to capture particles of different sizes. This leads to more thorough filtering, as larger particles are caught in the outer layers, while finer particles are captured in the inner layers.

Extended Filter Life: A thicker filter can hold more particles before becoming clogged, which extends its usable life and maintains efficiency over time. This reduces the frequency of filter replacement.

Higher Resistance in Thicker Filters: While thicker panel air filters are more efficient at trapping particles, they also tend to create greater airflow resistance, known as a pressure drop. As air moves through the filter, it encounters more material, which can slow down the airflow.

Impact on HVAC Systems: Increased airflow resistance means the HVAC system has to work harder to push air through the filter, which can lead to higher energy consumption and potential strain on the system. This can be particularly problematic if the filter’s resistance exceeds the system's capacity to handle it.

Balancing Efficiency and Resistance: Filter manufacturers design panel air filters with varying depths to strike a balance between filtration efficiency and acceptable airflow resistance. For example, pleated filters, which increase surface area without significantly increasing depth, can offer better efficiency with minimal impact on airflow.

Pleated Design: Many filters use pleated designs to increase surface area without substantially increasing the filter's thickness. This allows for higher filtration efficiency while keeping the pressure drop manageable.

Matching Filter to System: It’s essential to select a filter with the right thickness for the specific HVAC system. A filter that’s too thick may reduce airflow to the point where the system becomes less efficient, while a filter that’s too thin may not provide adequate filtration.

System Design Considerations: HVAC systems are designed with specific airflow rates in mind, and using a filter with excessive thickness can cause system inefficiencies. Ensuring that the filter matches the system’s specifications is critical to maintaining both airflow and filtration performance.

While a thicker or deeper panel air filter generally improves filtration efficiency by capturing more particles, it also increases airflow resistance, potentially leading to higher energy consumption. Finding the right balance between thickness, filtration efficiency, and airflow resistance is key to optimizing both air quality and system performance.

Are there any sustainable or environmentally friendly features of IFD air purification device?

What is the capacity of a cylindrical filter to capture contaminants before it needs to be replaced?

related products

Copyright 2023 Nantong Henka Environment Solutions Co.,Ltd. All Rights Reserved

English

English русский

русский Español

Español 简体中文

简体中文