From solutions to productions, we’re specialized in making the products you need.

News categories

Product categories

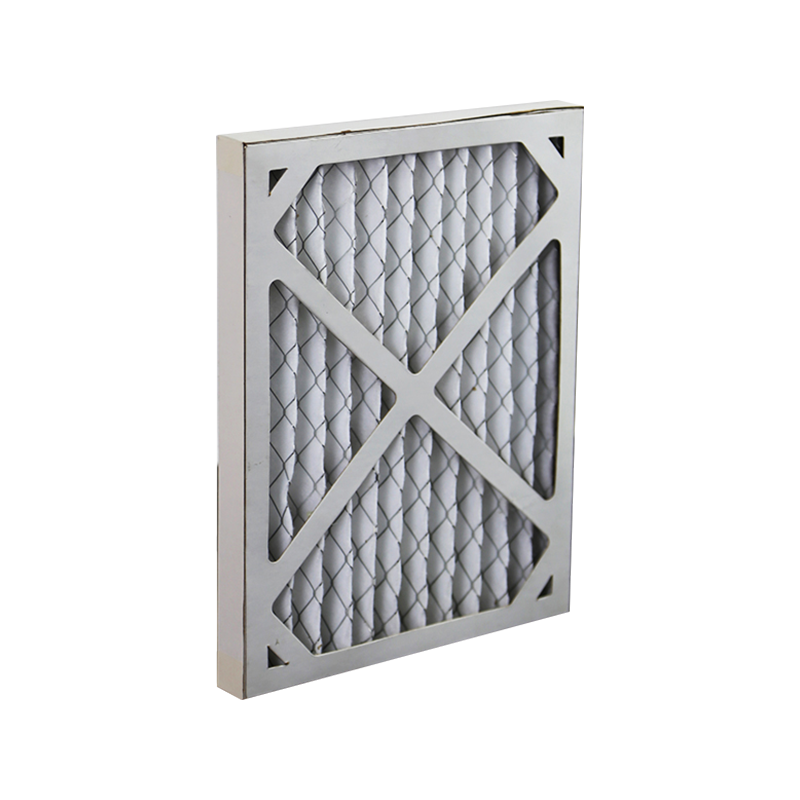

Primary Air Filter: A Key Component for Clean and Efficient Airflow

The primary air filter is a critical component in various systems, ranging from HVAC (Heating, Ventilation, and Air Conditioning) units to industrial machinery and automotive engines. Its primary function is to trap dust, debris, and other contaminants from entering sensitive equipment or environments, ensuring optimal performance and longevity.

Improved System Performance : By preventing contaminants from reaching vital components, primary air filters help maintain peak efficiency in HVAC systems, engines, and industrial equipment.

Extended Equipment Lifespan : Reducing wear and tear caused by abrasive particles extends the life of compressors, turbines, fans, and other mechanical parts.

Enhanced Air Quality : In residential and commercial settings, primary air filters contribute to healthier indoor environments by reducing allergens and pollutants.

Cost-Effectiveness : Regular replacement of primary air filters is relatively inexpensive compared to repairing or replacing damaged equipment due to clogs or contamination.

Easy Maintenance : Most primary air filters are simple to install and replace, making routine upkeep hassle-free.

Key Features of Primary Air Filters

Efficient Particle Capture : Designed to trap coarse particles effectively while allowing unrestricted airflow, ensuring minimal pressure drop across the filter.

Durable Construction : Made from robust materials capable of withstanding harsh conditions, such as high temperatures, humidity, or corrosive environments.

Variety of Media Types : Available in different media options (e.g., fiberglass, pleated paper, electrostatically charged synthetic fibers), offering flexibility based on specific requirements.

Customizable Sizes : Manufactured in standard and custom sizes to fit a wide range of systems, including central heating units, air conditioners, and industrial ventilation setups.

Reusability Options : Some primary air filters, particularly those made from foam or metal mesh, can be cleaned and reused multiple times, promoting sustainability.

Common Uses of Primary Air Filters

HVAC Systems : Installed in residential and commercial HVAC units to protect evaporator coils, blowers, and ductwork from dust accumulation, improving energy efficiency and comfort levels.

Automotive Engines : Used in vehicle air intake systems to prevent engine wear by blocking dirt and debris while allowing sufficient airflow for combustion processes.

Industrial Applications : Employed in manufacturing plants, power generation facilities, and food processing industries to safeguard expensive machinery and ensure product quality.

Medical Facilities : Vital for maintaining sterile environments in hospitals, laboratories, and pharmaceutical production areas by minimizing airborne contaminants.

Agricultural Equipment : Protects tractors, harvesters, and other farming machinery from dust, soil, and organic matter found in rural settings.

Primary air filters serve as the foundation for clean and efficient airflow in countless applications, providing essential protection for both equipment and people. Their ability to capture harmful particles while maintaining unrestricted airflow ensures reliable operation and improved performance. Whether you're managing an HVAC system, operating heavy machinery, or driving your car, investing in quality primary air filters is crucial for extending equipment lifespan, enhancing productivity, and promoting healthier living spaces. As technology advances, expect even more innovative designs and materials to emerge, further refining the capabilities of these indispensable components.

What are the advantages, features and uses of air filters?

Why Are True HEPA Filters Essential for Clean Air and Health?

related products

Copyright 2023 Nantong Henka Environment Solutions Co.,Ltd. All Rights Reserved

English

English русский

русский Español

Español 简体中文

简体中文